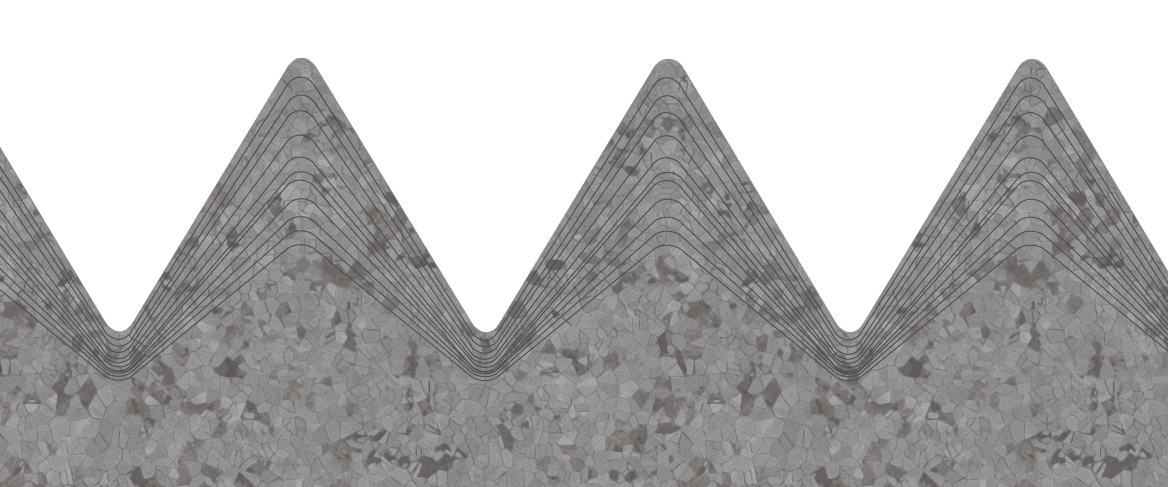

Flat dies made by cold forging

Flat thread rolling tooling manufactured with an innovative new cold forging process.

M6 x 1 x 2-1/8

Duplex #10 Flat Die

Cold Forging Technology

State-of-the-Art

We manufacture our flat thread rolling dies using a new patented cold forging process.

No cutting, no grinding.

cold Forging Features

Radius Root + Crest Run-out

During the cold forging process, a Radiused Crest Run-out (RCRO) is naturally created. By combining this feature with an industry standard Radiused Root Run-out (RRO), we are able to dramatically increase the die’s top edge strength.

Straight Start

The material flow during cold forging causes the die crests to underfill or flatten at the die Roll-on/Roll-off. This unique geometry helps square the blank to the die prior to rolling. This Straight Start feature has no effect of the thread form.

Mix + Match Dies

Due to the engineering of our cold forging process, our thread location is timed in the center of the die. This allows for any of our long or short dies to be used with any other.

Cold forging Strength

By cold forging our dies, the grain structure of the steel is compressed instead of removed, which improves the ultimate tensile strength and fatigue resistance of our die threads.

Interested in ADDITIONAL DIE SIZES & Types?

We are a start-up and are developing new cold formed thread profiles all the time.

If you would like to purchase a different thread type or die size, please let us know.